Overview

Nerd Gas Company is working to build a natural gas-to-liquids (GTL) conversion facility in Wyoming through a special purpose limited liability company, US GTL, LLC. The GTL facility will utilize a state-of-the-art modular design combining an existing processing technology with the well-known Fischer-Tropsch reaction. The proposed project will convert 10 mcf (thousand standard cubic feet) into 1 bpd (barrel per day) of clean diesel and naphtha.

Recent advances in horizontal drilling and hydraulic fracturing have engulfed the U.S. natural gas market, reducing natural gas prices and decoupling the traditional BTU trading basis of 6 mcf of natural gas to 1 barrel of oil. Natural gas to oil pricing ratios ($/mfc to $/bbl) have ranged from 25:1 to 50:1 since January 1, 2012. As exploration and production companies continue to drill for high valued oil and natural gas liquids, dry natural gas is becoming a low value byproduct and in some cases, an environmental nuisance. The US GTL proposed project leverages the price disparity between dry natural gas and liquid hydrocarbons.

Status

For the last three years, Nerd Gas has worked on procuring a site, selecting feasible technology, identifying capable partners, initiating the permitting phase and building local support for a Wyoming-based GTL facility. After evaluating four Wyoming sites, Nerd is in the process of securing a site with ample land for the current facility and expansion, water rights, rail access, gas pipeline access, off-take pipeline capacity and electrical power. Nerd has also contracted with an industry leader in modular engineering and design to complete a detailed design and cost estimate for a modular GTL facility. Initiation of feedstock and off-take agreements and permitting the facility is expected to begin in the fourth quarter of 2012.

Technology and Modular Design

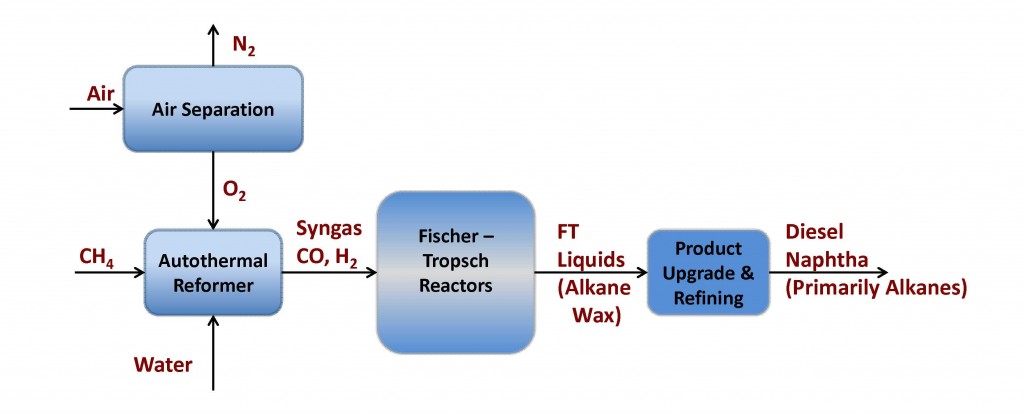

The design will incorporate traditional GTL technology into a modular design. Natural gas is first converted to synthesis gas via an autothermal reformer. The synthesis gas then flows to a Fischer-Tropsch reactor where a waxy hydrocarbon product is formed. The Fischer-Tropsch product stream is then upgraded using mature hydrofracking technology to form a blend of 80% diesel and 20% naphtha. The premium diesel product is sulfur-free with a cetane number greater than 70.

Modular design offers several advantages over conventional GTL projects:

1. Order of magnitude reduction in total project capital costs

2. Increased control of capital costs and reduced construction risks

3. Reduced socio-economic impacts throughout construction

4. Reduction of necessary gas reserves

5. Modules allow for rapid scale up and nationwide deployment with minimum engineering.